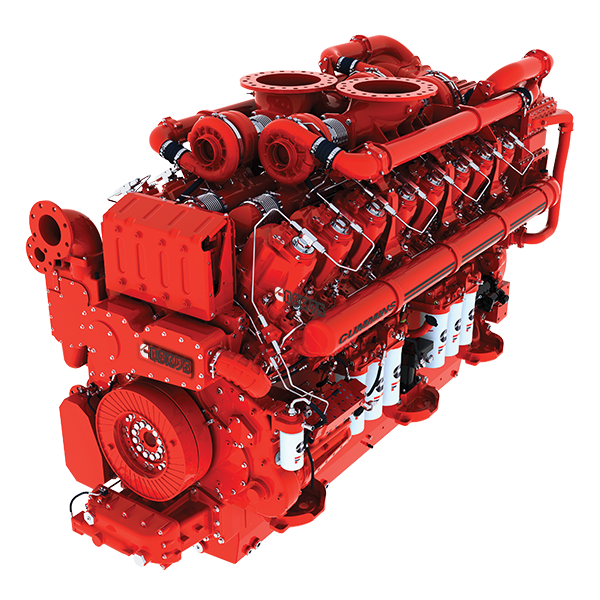

Cummins QSK95 for Rail

Torque:11671 - 12838 lb-ft

Certification:Tier 4 Final / Stage IIIB,EPA Tier 4,EU Stage III

Category:

>= 4000 HP

Keywords:

>= 4000 HP

- Product Description

- Specifications

- Ratings

- Maintenance

-

- Commodity name: QSK95 for Rail

Power:4000 - 4400 hp<br> Torque:11671 - 12838 lb-ft<br> Certification:Tier 4 Final / Stage IIIB,EPA Tier 4,EU Stage III

The Path to Zero in Passenger - from Tier 0 to Tier 4 with the QSK95:

train equipped with qsk95 engine70% reduction in CO2

95% reduction in PM

85% reduction in HC

86% reduction in NOx

92 units in revenue service

17.7M miles (and counting)

Over 1.1M hours

CO2 savings of 380 Metric Tons per locomotive per year compared to the engine its replacing

Equivalent to 81 passenger cars taken off the road

EPA's Greenhouse Gas Equivalencies Calculator

Features & Benefits

Superior Power Density: The QSK95 produces up to 4,400 hp at 1,800 rpms with only 16 cylinders. Four fewer cylinders than other high-speed locomotive engines gives the QSK95 better reliability with fewer moving parts.

Advanced Power Cylinder Design: This technology reduces the amount of cylinder wear, provides better breathing and thermal stresses, bringing together high-speed efficiency with durability.

Modular Common Rail Fuel System (MRS): This system maintains high injection pressures regardless of engine speed for exceptional performance at every rpm. Compared to unit injection systems, it provides improved response and load pickup with lower noise and vibration.

Quad Single-Stage Turbochargers: Four compact turbochargers deliver best in-class clean acceleration, tight packaging, excellent serviceability and unmatched cost-effectiveness

Meets Tier 4 and Stage 5 Emissions Requirements: The QSK’s compact size provides room for a proven, simplistic selective catalytic reduction (or SCR) system instead of an exhaust gas recirculation system. Using the SCR system allows the QSK95 to meet Tier 4 and Stage 5 emissions requirements, operate at lower temperatures, use a smaller cooling system and provide better fuel economy with fluid savings of 5-7% compared to other Tier 4 solutions.

Two-stage Aftercooling: Two-stage aftercooling provides a better-balanced cooling system that considerably reduces radiator sizing and cost. Tier 4/Stage IIIB engines will have heat rejection similar to Tier 3/Stage IIIA engines.

Eliminator Oil Filtration: A highly efficient combination of self-cleaning micromesh filters and twin centrifuges enables the QSK95 to achieve industry-demanded extended service intervals.

PrevenTech Engine Monitoring: Using advanced engine monitoring, analytics and prognostics, data is analyzed remotely to evaluate performance and identify potential issues which are reported back to customers through alter notifications. PrevenTech offers your locomotives experience extended service intervals, reduced repair times and maximum uptime.

184-Day Service Intervals: The QSK95 can meet the service schedules of both high-speed and medium-speed rail. -

Specifications

Base engine without aftertreatment Horsepower 4,000-4,400 hp / 2,983-3,281 kW Governed Speed 1,800 rpm Displacement 5,797 cu in / 95 L Bore and Stroke 7.48 x 8.27 in / 190 x 210 mm Number of cylinders 16 Dry weight 29,300 lb / 13,290 kg Length 144 in / 365 cm Width 68 in / 173 cm Height 97 in / 246 cm -

Ratings

Rated power hp (kW) @ rpm QSK95 4,400 (3,281) @1,800 4,200 (3,132) @ 1,800 4,000 (2,983) @ 1,800

Packaging and delivery

Jining Yikang International Trade Co., Ltd. is a high-end intelligent equipment manufacturing company integrating production, learning and research. The company is located in Jining National High-tech Zone, covers an area of 40,000 square meters, and has R&D centers, office buildings, production workshops, warehouses, test fields and other facilities.

Customer visit

The company was established in 2012 and has the qualifications of authorized dealers of many well-known diesel engine brands. The main business includes the sales and maintenance of Cummins engines and accessories, as well as the production and sales of small engines, generator sets and remanufactured engines.

Factory appearance

The company implements the strategy of "rooted in the local area and serving the world" and has established stable cooperative relations with Cummins, Shandong University, Engineering Machinery Association and other units. Adhering to the mission of "driving the world forward and achieving the most beautiful life", with the purpose of "innovation is inexhaustible, customer achievement", to build a more efficient and cleaner future power world.

Brochures

RELATED PRODUCTS